What are SMD, DIP, LOB, COB, GOB, and MIP?

LED display technology has rapidly evolved over the last few decades, moving from bulky, low-resolution modules to ultra-fine pixel pitch and seamless visual experiences. Different LED packaging methods define how LED chips are manufactured, installed, and protected, which directly affects screen performance, durability, and cost.

The most common packaging technologies today include SMD, DIP, LOB, COB, GOB, and MIP. Each has its own strengths, limitations, and ideal application scenarios.

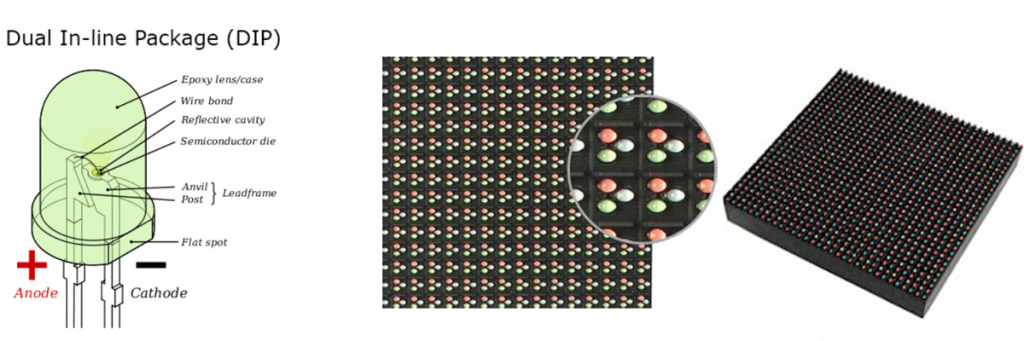

1.DIP (Dual In-line Package)

DIP is one of the earliest LED packaging methods. It uses three separate diodes—red, green, and blue—encased individually and mounted through holes in the printed circuit board (PCB).

Typical Chip Sizes:

DIP346, DIP546 (the numbers denote approx. 3 mm or 5 mm lamp diameter and 4×6 mm lead spacing).

Installation:

The diodes are fixed by pin-through-hole soldering, making them mechanically strong and suitable for outdoor use. However, the size of the components makes DIP displays heavier and thicker.

Key Features:

Brightness: Extremely high, suitable for direct sunlight conditions.

Durability: Strong resistance to harsh environments such as rain, wind, and temperature shifts.

Pixel Pitch: Limited resolution, commonly P10, P16

Applications

--Highway and city billboards visible from >50 m

--Stadium perimeter screens and large outdoor scoreboards.

--Coastal or desert environments with salt or UV exposure.

2.LOB (Light on Board)

LOB is a newer approach where LED chips are directly integrated into a board or module, similar to COB but with more emphasis on simplified mass production. It aims to improve reliability while reducing production costs.

Typical Chip Size:

Custom micro-LEDs, generally <1.5 mm.

Installation:

Multiple microchips are bonded directly onto a substrate in dense arrays, minimizing spacing between pixels.

Key Features:

Higher Uniformity: LEDs are closely packed, improving consistency.

Lower Cost Manufacturing: Simplifies production compared to COB.

Durability: Provides better resistance than SMD but not as strong as GOB or COB.

Use Case: Mid- to high-resolution displays, both indoor and semi-outdoor.

Applications

--Airport and shopping-mall signage that needs high brightness and smooth color.

--Semi-outdoor window displays or large retail atriums.

--Rental/event screens where moderate ruggedness and cost control matter.

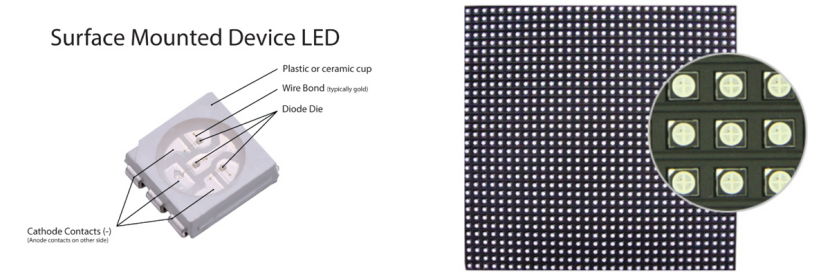

3.SMD (Surface-Mounted Device)

SMD integrates red, green, and blue chips into a single compact package, soldered directly onto the PCB surface. This reduces size and enables higher pixel density compared to DIP.

Typical Packages:

SMD2121 (2.1 × 2.1 mm, indoor fine pitch), SMD2727 (2.7 × 2.7 mm, outdoor mid-pitch), SMD3535 (3.5 × 3.5 mm, high-brightness outdoor).

Installation:

The chips are mounted on the surface without drilling holes, resulting in thinner, lighter panels. Modular design allows quick assembly and maintenance.

Key Features:

High Pixel Density: Provides sharper images for indoor displays.

Color Quality: RGB-in-one design delivers smooth blending and accurate colors.

Versatility: Common for both indoor and outdoor screens, although it dominates indoor usage.

Applications

--Indoor advertising walls, retail shopfronts, exhibition halls.

--Rental stage backdrops (P3.91, P4.81).

--Transportation control rooms, corporate boardrooms, and broadcast studios.

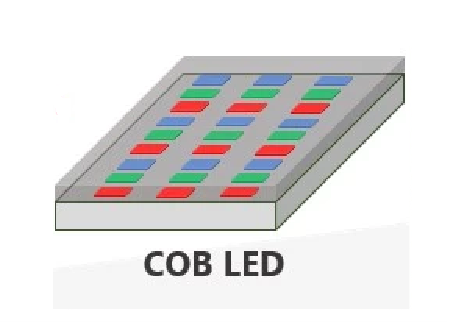

4.COB (Chip on Board)

COB takes integration further by embedding bare LED chips directly into the board, then sealing them with protective resin. This method eliminates the need for separate packaging.

Typical Chip Sizes:

Mini LED (≈50–100 µm), Micro LED (≤50 µm).

Installation:

Face-up Bonding: Chips are mounted facing outward; better heat dissipation but more exposure.

Flip-chip Bonding: Chips are inverted and connected from the back, increasing reliability, density, and lifespan.

Key Features:

Ultra-High Density: Supports very fine pixel pitches under 1mm.

Seamless Display: Smooth, gap-free visuals.

Protection: Resin coating prevents dust, static, and water damage.

Applications

--control centers and 24/7 surveillance rooms.

--Premium conference and boardroom displays.

--High-end home theater or Micro LED TVs requiring frameless design.

5.GOB (Glue on Board)

GOB is not a packaging method itself but rather a protective technique. It applies a transparent epoxy “glue” layer over SMD or other packaged LEDs.

Installation:

After assembling the display module, a resin coating is applied over the LED surface, sealing it against impact and contamination.

Key Features:

Protection: Strong resistance to water, dust, and shock.

Cost-Effective: Adds durability without changing core LED packaging.

Brightness: Maintains brightness while improving longevity.

Applications

--Touring concert and trade-show rental screens that face frequent handling.

--Outdoor bar façades and storefront signage exposed to impact or weather.

--Mobile LED truck displays subject to vibration.

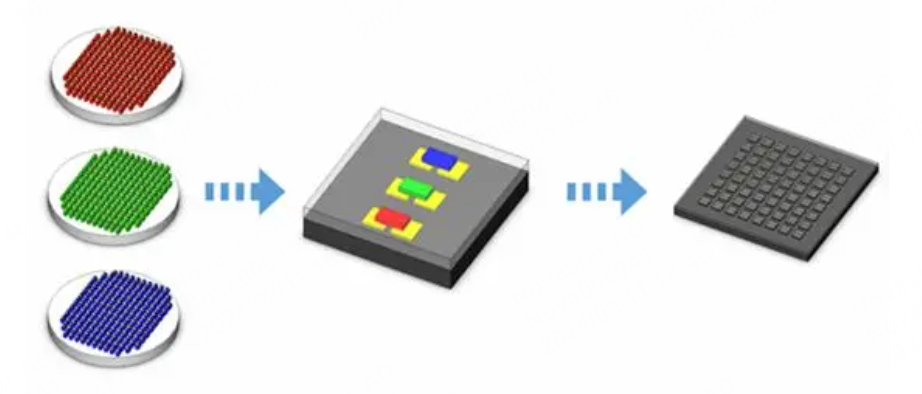

6.MIP (Micro LED in Package)

MIP combines the advantages of Micro LED and traditional packaging. Micro LEDs are transferred to substrates in large batches, then cut into independent or multi-chip packages.

Typical Chip Size:

Micro LED 20–50 µm; package footprint <0.5 mm.

Installation:

The packaged Micro LEDs can be mounted using existing surface-mount (SMT) production lines, making them compatible with SMD processes while offering finer pixel pitches.

Key Features:

Ultra-Fine Pixel Pitch: Below 1mm, ideal for 4K/8K small-pitch displays.

Brightness and Contrast: Exceptional performance with uniformity and vivid colors.

Flexibility: Easy testing, repair, and mass production.

Applications

--Next-generation ultra-high-definition video walls.

--VR/AR head-mounted displays requiring extreme resolution.

--Premium automotive and medical displays demanding high contrast and long life.

Use-Case Guidance: Which Technology for Which Scenario

To choose the right LED packaging, you usually match your project to a few main criteria:

1.Viewing Distance & Pixel Pitch:

Closer viewing → need finer pitch (COB, MIP, SMD small-pitch).

Far viewing (billboards, signage) → DIP or SMD with larger pitch

2.Ambient Light / Brightness Requirements:

Outdoor, direct sun → need very high brightness + protective features (DIP, GOB, LOB). Indoor or low-light / controlled environments → more flexibility, can emphasize resolution and visual comfort.

3.Durability & Environment:

For dusty, humid, or physically exposed locations, GOB and LOB offer extra protection. For mobile / rental / event screens with frequent handling, also consider those with better mechanical protection

4.Cost vs Maintenance vs Quality Trade-off:

Lower cost upfront (basic SMD, DIP) may cost more later in maintenance or lower image stability.

Premium packaging (COB, MIP, GOB, LOB) costs more initially but often gives longer service life and better visual/performance consistency.

👉 Ready to find the best solution for your project? Contact our team today, and let’s make your LED display work smarter and shine brighter.

Contact BRIGHTEN LED now!

Contact

Office : +86 0755-89341658

Mobile:+86-13924645917

Contact: Sita

Feedback