Differerence Between SMD and DIP LED, which one is Better?

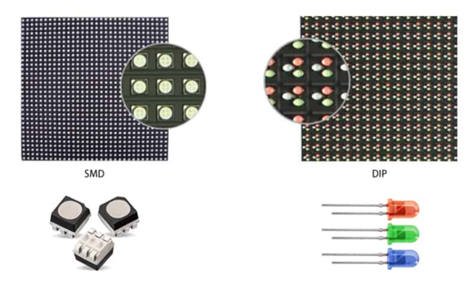

1. Different encapsulation technology

*DIP(Dual in-line package) LED each pixel is made of three independent color (RGB) LED bulbs, each bulb have rectangular housing and two long parallel pins inserted into PCB pad. So its structure is more weather resistant as they are individual package.

*SMD (Surface Mounted Devices) LED its components are mounted directly onto the surface of PCB pads, the SMT lamp packaged with three different colors of RGB LED chip packaged in the same gel at a certain interval.

2. Application

DIP LED is used for outdoor and SMD LED is used for both indoor and outdoor. Due to production technique of DIP, it can't produce small pixel pitch below P10. Normally DIP LED display is P10, P16, P20. While SMD LED can be smaller pixel pitch, now can reach to P0.7, SMD can do more higher resolution and higher color contrast.

3. Brightness

DIP LED has higher brightness than SMD, because each R,G,B lamps in DIP has independent circuit, so each lamps can reach the maximum brightness current easily. DIP cam reach up to 10,000 nit-20000ni while for SMD normally is 5000-1000 nit.

4. Color Performance

SMD LED has better color performance than DIP LED. The distance between RGB is closer in SMD LED display. The SMD LED surface can be treated with diffuse reflection, resulting in no granular effect and good color uniformity.

5. Protection

DIP LED has better protection than SMD LED. Due to the production technique of DIP LED, it is much easy to do protection in waterproof, shockproof etc.

Contact

Office : +86 0755-89341658

Mobile:+86-13924645917

Contact: Sita

Feedback